Sustainability & Renewable Energy: Eco-Friendly Packaging Solutions

Explore the role of sustainability and renewable energy in eco-friendly packaging. Understand the benefits, challenges, and actionable steps to implement sustainable solutions for a greener future.

In today's rapidly evolving world, the concept of sustainability has transcended beyond being a mere buzzword to becoming a cornerstone of modern business practices. As global awareness about environmental degradation intensifies, businesses are increasingly recognizing the critical role they play in mitigating their ecological footprint. This paradigm shift is not only driven by ethical imperatives but also by consumer demand for environmentally responsible products and services. The integration of renewable energy and eco-friendly packaging solutions into corporate strategies has emerged as a pivotal step toward achieving sustainability goals.

The urgency of addressing climate change and resource depletion cannot be overstated. With rising greenhouse gas emissions, deforestation, and plastic pollution threatening ecosystems worldwide, companies are under mounting pressure to adopt sustainable practices. Governments and regulatory bodies are enacting stringent policies to encourage or mandate eco-conscious operations, further amplifying the need for businesses to align with these standards. In this context, renewable energy sources such as solar, wind, and hydropower have gained significant traction as viable alternatives to fossil fuels, offering both environmental and economic benefits.

Simultaneously, the focus on eco-friendly packaging has become a key priority for industries ranging from retail to manufacturing. Traditional packaging materials, particularly single-use plastics, contribute significantly to environmental harm, with millions of tons ending up in landfills and oceans annually. By transitioning to biodegradable, recyclable, or reusable packaging options, businesses can drastically reduce waste generation while enhancing their brand image. Consumers, now more informed and discerning than ever, are actively seeking out brands that prioritize sustainability, making it imperative for companies to innovate in this space.

This article delves into the intricate relationship between sustainability , renewable energy , and eco-friendly packaging solutions , exploring how these elements collectively contribute to a greener future. We will examine the latest advancements in renewable energy technologies, evaluate the lifecycle impacts of various packaging materials, and provide actionable insights for businesses aiming to integrate sustainable practices into their operations. Through comprehensive analysis and real-world examples, we aim to equip readers with the knowledge and tools necessary to make informed decisions that benefit both their organizations and the planet.

The Environmental Impact of Traditional Packaging Materials

Traditional packaging materials, predominantly derived from non-renewable resources, have long been a cornerstone of global commerce. However, their widespread use has led to profound environmental consequences, many of which are irreversible. Among the most prevalent materials are plastic , polystyrene , and non-recyclable composites , each contributing uniquely to ecological degradation. Understanding the lifecycle of these materials—from production to disposal—reveals the extent of their detrimental impact on ecosystems and human health.

Plastic Pollution: A Global Crisis

Plastic, particularly single-use varieties, dominates the packaging industry due to its durability, lightweight nature, and cost-effectiveness. However, these very attributes make it a persistent pollutant. Globally, over 300 million tons of plastic are produced annually, with nearly half designated for single-use purposes. Shockingly, less than 10% of this plastic is recycled, leaving the remainder to accumulate in landfills, waterways, and natural habitats. The decomposition of plastic can take hundreds of years , during which time it breaks down into microplastics—tiny particles that infiltrate soil, water, and even the air we breathe.

The environmental ramifications of plastic pollution are staggering. Marine ecosystems bear the brunt of this crisis, with an estimated 8 million tons of plastic entering oceans each year. This debris poses a direct threat to marine life, causing entanglement, ingestion, and habitat destruction. For instance, sea turtles often mistake floating plastic bags for jellyfish, leading to fatal blockages in their digestive systems. Similarly, seabirds ingest plastic fragments, which can puncture internal organs or lead to starvation by creating a false sense of fullness. Beyond wildlife, microplastics have entered the human food chain, raising concerns about potential health risks, including endocrine disruption and carcinogenic effects.

Polystyrene: A Hidden Hazard

Polystyrene, commonly known as Styrofoam, is another widely used packaging material notorious for its environmental toll. Despite its insulating properties and low production costs, polystyrene is non-biodegradable and highly resistant to natural degradation processes. When improperly disposed of, it breaks into smaller pieces that contaminate soil and water. Moreover, the production of polystyrene involves the use of hazardous chemicals, such as styrene, which is classified as a potential carcinogen by health authorities.

The lightweight nature of polystyrene makes it particularly prone to dispersal by wind and water, exacerbating its spread across ecosystems. Once fragmented, it becomes nearly impossible to clean up, especially in aquatic environments where it disrupts nutrient cycles and harms aquatic organisms. Furthermore, when incinerated—a common method of disposal in some regions—polystyrene releases toxic fumes, including benzene and styrene monomers, which contribute to air pollution and pose health risks to nearby communities.

Non-Recyclable Composites: A Recycling Nightmare

Non-recyclable composite materials, such as laminated plastics and metallized films, represent another significant challenge in the realm of traditional packaging. These materials are engineered for specific functional properties, such as moisture resistance or extended shelf life, but their complex composition renders them incompatible with existing recycling infrastructure. As a result, they often end up in landfills, where they persist indefinitely due to their inability to decompose naturally.

The prevalence of non-recyclable composites in food packaging, pharmaceuticals, and e-commerce logistics underscores the difficulty of transitioning away from these materials. Their production relies heavily on petrochemical derivatives, further depleting finite resources and increasing carbon emissions. Additionally, the lack of scalable alternatives has perpetuated their use, despite growing awareness of their environmental drawbacks.

Resource Depletion and Carbon Emissions

Beyond pollution, the production of traditional packaging materials contributes significantly to resource depletion and greenhouse gas emissions. The extraction and refining of petroleum-based raw materials, such as crude oil and natural gas, are energy-intensive processes that release substantial amounts of carbon dioxide into the atmosphere. For example, the manufacture of virgin plastic accounts for approximately 6% of global oil consumption , a figure projected to rise as demand for packaging continues to grow.

Moreover, the transportation of bulky packaging materials adds to their carbon footprint, particularly when sourced from distant locations. The cumulative effect of these processes exacerbates climate change, undermines biodiversity, and strains already limited natural resources. As the global population expands and consumption patterns intensify, the environmental burden of traditional packaging is set to worsen unless decisive action is taken.

A Call for Change

The environmental impact of traditional packaging materials is undeniable, manifesting in widespread pollution, resource depletion, and ecosystem disruption. Addressing this issue requires a fundamental shift toward sustainable alternatives that prioritize circularity, biodegradability, and reduced environmental harm. By understanding the lifecycle and consequences of conventional materials, businesses and consumers alike can make informed choices that pave the way for a more sustainable future.

The Role of Renewable Energy in Sustainable Packaging Production

As the global push for sustainability gains momentum, the integration of renewable energy into packaging production processes has emerged as a transformative solution. Renewable energy sources, including solar , wind , hydropower , and biomass , offer a cleaner and more sustainable alternative to fossil fuels traditionally used in manufacturing. By harnessing these energy sources, businesses can significantly reduce their carbon footprint, lower operational costs, and align their practices with environmental stewardship goals. This section explores the mechanisms through which renewable energy contributes to sustainable packaging production, highlighting its benefits and practical applications.

Reducing Carbon Emissions Through Clean Energy

One of the most compelling advantages of renewable energy is its ability to drastically cut greenhouse gas emissions associated with packaging production. Conventional manufacturing processes rely heavily on coal, oil, and natural gas, which release substantial amounts of carbon dioxide and other pollutants into the atmosphere. In contrast, renewable energy sources generate electricity without emitting harmful gases, thereby mitigating the environmental impact of energy-intensive activities like extrusion, molding, and printing.

For instance, solar power installations on manufacturing facilities can supply a significant portion of the energy required for production. Photovoltaic panels convert sunlight into electricity, providing a reliable and sustainable energy source that reduces dependency on grid-supplied power derived from fossil fuels. Similarly, wind turbines installed near production sites can generate clean energy to power machinery, lighting, and heating systems. These technologies not only minimize emissions but also contribute to long-term energy independence, shielding businesses from volatile fossil fuel prices.

Energy Efficiency and Cost Savings

Beyond environmental benefits, renewable energy adoption enhances operational efficiency and delivers tangible financial savings. Many renewable technologies, such as solar panels and wind turbines, have seen significant cost reductions over the past decade, making them increasingly accessible to businesses of all sizes. Once installed, these systems require minimal maintenance and operate at a fraction of the cost of traditional energy sources. Over time, the savings accrued from reduced energy bills can offset the initial investment, resulting in a positive return on investment (ROI).

Additionally, renewable energy systems can be integrated with advanced energy management technologies to optimize energy consumption. For example, smart grids and energy storage solutions allow manufacturers to store excess energy generated during peak production hours and utilize it during periods of high demand. This ensures a consistent and reliable energy supply while minimizing waste. By adopting such innovations, businesses can streamline their operations, enhance productivity, and reduce their overall environmental impact.

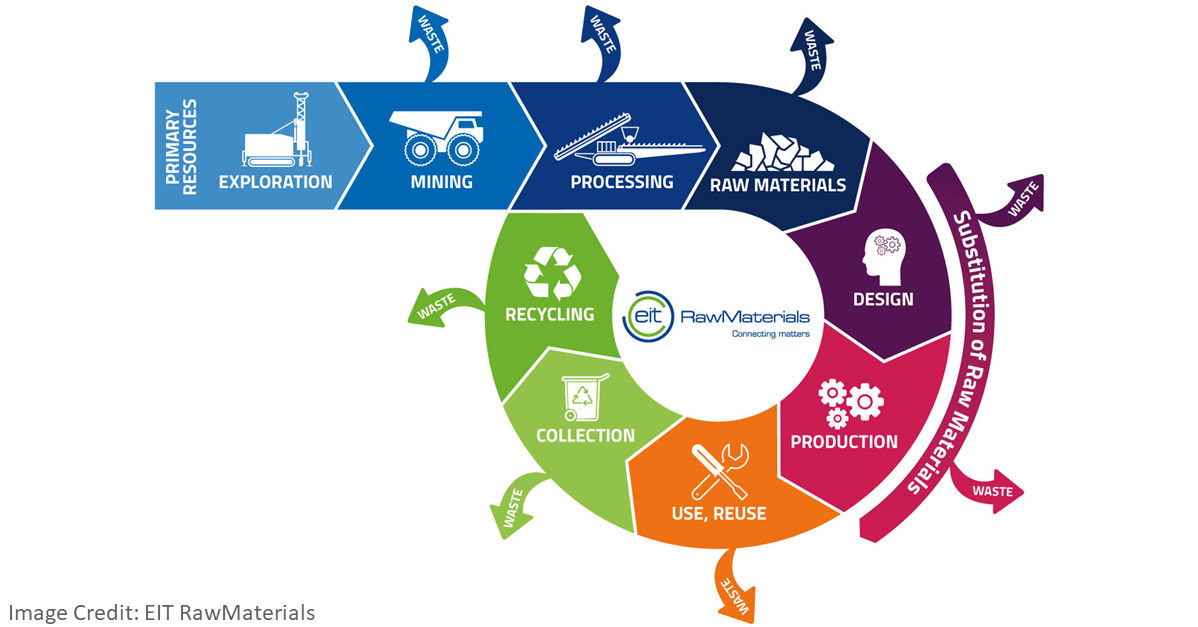

Supporting Circular Economy Initiatives

Renewable energy plays a crucial role in advancing the principles of the circular economy , which emphasizes resource efficiency, waste reduction, and closed-loop systems. In the context of packaging production, renewable energy supports the development of sustainable materials and processes that align with circularity goals. For example, bio-based packaging materials derived from agricultural waste or plant fibers require energy-intensive processing to transform them into usable products. By powering these processes with renewable energy, manufacturers can ensure that the entire lifecycle of the packaging—from raw material extraction to end-of-life disposal—is environmentally responsible.

Furthermore, renewable energy facilitates the implementation of innovative recycling technologies. Advanced recycling methods, such as chemical recycling and pyrolysis, require significant energy inputs to break down complex materials into their constituent components. Using renewable energy to power these processes ensures that recycled materials retain their environmental benefits, enabling businesses to create packaging solutions that are both sustainable and economically viable.

Case Studies: Success Stories in Renewable Energy Integration

Several forward-thinking companies have already demonstrated the feasibility and benefits of integrating renewable energy into packaging production. For example, a leading beverage manufacturer recently installed a 20-megawatt solar farm adjacent to its bottling facility, enabling it to meet 70% of its energy needs through solar power. This initiative not only reduced the company’s carbon emissions by thousands of metric tons annually but also positioned it as a leader in sustainable manufacturing practices.

Similarly, a global e-commerce giant has committed to powering its fulfillment centers entirely with renewable energy by 2030. To achieve this goal, the company has invested in large-scale wind farms and rooftop solar installations, ensuring that its packaging operations remain aligned with its broader sustainability objectives. These efforts have earned the company widespread recognition and consumer trust, underscoring the competitive advantage of renewable energy adoption.

Policy Incentives and Industry Collaboration

Governments and regulatory bodies worldwide are actively promoting the adoption of renewable energy through incentives, subsidies, and mandates. Tax credits, grants, and feed-in tariffs are among the financial mechanisms designed to encourage businesses to transition to clean energy. For packaging manufacturers, these incentives can significantly reduce the upfront costs of renewable energy projects, making them more accessible and appealing.

Industry collaboration also plays a vital role in accelerating the adoption of renewable energy. Partnerships between manufacturers, energy providers, and research institutions foster innovation and knowledge sharing, driving the development of cutting-edge technologies and best practices. By working together, stakeholders can overcome barriers to implementation and create scalable solutions that benefit the entire packaging ecosystem.

A Path Toward Sustainable Growth

The integration of renewable energy into packaging production represents a critical step toward achieving sustainability goals. By reducing carbon emissions, enhancing energy efficiency, and supporting circular economy initiatives, renewable energy empowers businesses to create packaging solutions that are both environmentally responsible and economically viable. As technological advancements continue to drive down costs and improve accessibility, the adoption of renewable energy is poised to become a standard practice in the packaging industry, paving the way for a greener and more sustainable future.

Exploring Eco-Friendly Packaging Materials and Innovations

The quest for eco-friendly packaging solutions has spurred a wave of innovation, leading to the development of materials that prioritize environmental sustainability without compromising functionality. These materials are designed to address the shortcomings of traditional packaging by offering biodegradability, recyclability, and reduced resource consumption. From plant-based polymers to advanced compostable films, the range of options available today reflects a concerted effort to redefine the packaging landscape. This section delves into the most promising eco-friendly packaging materials and highlights the groundbreaking innovations driving their adoption.

Bioplastics: Harnessing Nature’s Potential

Among the most prominent alternatives to conventional plastics are bioplastics , which are derived from renewable biological sources such as corn starch, sugarcane, and cellulose. Unlike petroleum-based plastics, bioplastics are designed to break down more readily in natural environments, reducing their persistence in ecosystems. Two primary categories of bioplastics dominate the market: PLA (polylactic acid) and PHA (polyhydroxyalkanoates) .

PLA, made from fermented plant starch, is widely used in food packaging, disposable cutlery, and textiles. It is prized for its transparency, rigidity, and ability to decompose under industrial composting conditions. PLA’s versatility has made it a popular choice for brands seeking to replace single-use plastics with a more sustainable option. Similarly, PHA, produced by bacterial fermentation of sugars or lipids, offers superior biodegradability, breaking down even in marine environments. Its flexibility and compatibility with existing manufacturing processes make it an attractive alternative for flexible packaging applications.

Despite their advantages, bioplastics face challenges related to scalability and end-of-life management. While they degrade more efficiently than traditional plastics, they often require specific conditions, such as high temperatures and microbial activity, to fully decompose. Addressing these limitations necessitates advancements in waste management infrastructure and consumer education to ensure proper disposal.

Mushroom Packaging: A Breakthrough in Biodegradability

Another revolutionary material gaining traction is mushroom packaging , created from mycelium—the root structure of fungi. This innovative solution involves growing mycelium around agricultural waste, such as corn husks or sawdust, to form a durable, foam-like material. Once molded into desired shapes, the packaging is dried to halt further growth, resulting in a product that is both lightweight and biodegradable.

Mushroom packaging excels in applications requiring cushioning and insulation, such as protective packaging for electronics and fragile goods. Its biodegradability is unparalleled; when discarded, it decomposes naturally within weeks, enriching the soil with organic matter. Companies like Dell and IKEA have already adopted mushroom packaging for select products, demonstrating its viability as a scalable solution. However, scaling production to meet global demand remains a challenge, requiring investments in cultivation facilities and streamlined manufacturing processes.

Edible Packaging: Redefining Waste Reduction

The concept of edible packaging represents a bold leap toward eliminating waste altogether. Made from natural ingredients such as seaweed, rice, or potato starch, edible packaging is designed to be consumed alongside the product it contains. This innovation is particularly relevant for single-serving items, such as condiments, beverages, and snacks, where traditional packaging often generates unnecessary waste.

Seaweed-based films, for instance, have gained attention for their transparency, flexibility, and nutritional value. Brands like Notpla and Loliware have pioneered edible water pods and cups, showcasing the potential of this technology to revolutionize the food and beverage industry. While edible packaging holds immense promise, its adoption faces hurdles related to consumer acceptance, shelf life, and cost competitiveness. Overcoming these barriers will require continued research and collaboration between scientists, manufacturers, and retailers.

Recycled and Upcycled Materials: Closing the Loop

The use of recycled and upcycled materials has emerged as a cornerstone of sustainable packaging strategies. Recycled paper, cardboard, and plastics are widely employed in packaging design, offering a second life to materials that would otherwise end up in landfills. Advances in recycling technologies have expanded the scope of materials that can be repurposed, including multilayer plastics and mixed-material composites.

Upcycling takes this concept a step further by transforming waste materials into higher-value products. For example, discarded fishing nets and fabric scraps are being converted into durable packaging materials through innovative processes. Brands like Adidas and Patagonia have embraced upcycled materials in their product lines, setting a precedent for the packaging industry to follow. By prioritizing recycled and upcycled materials, businesses can reduce their reliance on virgin resources and contribute to a circular economy.

Compostable Films and Coatings: Bridging Functionality and Sustainability

Compostable films and coatings represent another frontier in eco-friendly packaging innovation. These materials are engineered to break down completely in composting environments, leaving no toxic residues behind. Derived from plant-based sources such as corn, cassava, and algae, compostable films are ideal for applications requiring barrier properties, such as food packaging and sachets.

Recent advancements have enhanced the performance of compostable films, enabling them to rival traditional plastics in terms of strength, flexibility, and shelf life. For instance, nanocellulose coatings derived from wood pulp offer exceptional oxygen and moisture barriers, extending the freshness of perishable goods. While compostable films hold great potential, their widespread adoption depends on the availability of industrial composting facilities and clear labeling to guide consumers on proper disposal.

Smart Packaging: Integrating Technology with Sustainability

The intersection of sustainability and technology has given rise to smart packaging , which incorporates sensors, indicators, and digital features to enhance functionality while minimizing waste. Smart packaging solutions can monitor product freshness, track supply chain logistics, and provide interactive experiences for consumers. For example, time-temperature indicators embedded in food packaging alert users to spoilage, reducing food waste and improving safety.

To align with sustainability goals, smart packaging is increasingly designed with eco-friendly materials and energy-efficient components. Biodegradable sensors and printed electronics made from renewable resources are emerging as viable alternatives to conventional electronic components. By integrating smart features with sustainable materials, brands can deliver value-added solutions that resonate with environmentally conscious consumers.

Driving Innovation Through Collaboration

The development and adoption of eco-friendly packaging materials hinge on collaboration across industries, academia, and government agencies. Research institutions are spearheading efforts to discover new materials and optimize existing ones, while startups and established companies are investing in pilot projects and commercial-scale production. Policymakers play a crucial role by incentivizing sustainable practices and establishing standards for biodegradability and recyclability.

By fostering partnerships and embracing innovation, the packaging industry can accelerate the transition to a more sustainable future. The materials and technologies highlighted in this section underscore the vast potential of eco-friendly packaging to address environmental challenges while meeting the demands of modern commerce.

The Economic Benefits of Adopting Eco-Friendly Packaging

Transitioning to eco-friendly packaging is not merely an environmental imperative but also a strategic business decision that yields significant economic advantages. While the initial perception may associate sustainable practices with increased costs, the reality is far more nuanced. Businesses that embrace eco-friendly packaging often experience enhanced profitability, improved brand equity, and long-term resilience in an increasingly competitive marketplace. This section examines the multifaceted economic benefits of adopting sustainable packaging solutions, emphasizing their potential to drive growth and foster innovation.

Cost Savings Through Material Efficiency

One of the most immediate economic benefits of eco-friendly packaging lies in its emphasis on material efficiency . Sustainable packaging designs prioritize the use of fewer resources, lighter materials, and optimized dimensions, all of which contribute to reduced material costs. For instance, replacing bulky, non-recyclable packaging with lightweight, biodegradable alternatives minimizes the amount of raw material required per unit, lowering procurement expenses. Additionally, the use of recycled materials often proves more cost-effective than sourcing virgin resources, particularly as global demand for finite raw materials drives up prices.

Moreover, eco-friendly packaging frequently results in logistics savings . Lightweight and compact designs reduce shipping weights and volumes, leading to lower transportation costs. This is particularly advantageous for e-commerce businesses, where shipping expenses constitute a significant portion of operational budgets. By optimizing packaging dimensions and materials, companies can maximize load efficiency, reduce fuel consumption, and minimize carbon emissions, further enhancing cost savings while aligning with sustainability goals.

Enhanced Brand Value and Consumer Loyalty

In today’s hyper-competitive market, brand differentiation is paramount, and eco-friendly packaging serves as a powerful tool for achieving this. Consumers are increasingly prioritizing sustainability in their purchasing decisions, with studies indicating that a majority of shoppers are willing to pay a premium for products packaged in environmentally responsible ways. By adopting sustainable packaging, businesses can position themselves as leaders in corporate social responsibility, strengthening their brand image and fostering deeper connections with environmentally conscious consumers.

The ripple effect of enhanced brand value extends to customer loyalty and retention. Consumers who perceive a brand as environmentally responsible are more likely to develop long-term relationships with it, leading to repeat purchases and positive word-of-mouth marketing. This loyalty translates into stable revenue streams and reduced customer acquisition costs, as satisfied customers become advocates for the brand. Furthermore, businesses that align with sustainability values often enjoy greater visibility and credibility, attracting partnerships and collaborations that amplify their market presence.

Regulatory Compliance and Risk Mitigation

As governments worldwide implement stricter environmental regulations, compliance has become a critical consideration for businesses. Companies that proactively adopt eco-friendly packaging solutions are better positioned to navigate evolving regulatory landscapes, avoiding fines, penalties, and reputational damage associated with non-compliance. For example, bans on single-use plastics and mandates for recyclable or biodegradable packaging are becoming increasingly common, particularly in regions like the European Union and North America.

Beyond regulatory adherence, sustainable packaging mitigates risks related to resource scarcity and supply chain disruptions. By reducing dependency on finite resources and non-renewable materials, businesses can insulate themselves from price volatility and geopolitical uncertainties. Additionally, the adoption of circular economy principles—such as designing for recyclability and reusability—ensures a steady supply of materials, reducing reliance on external suppliers and enhancing operational resilience.

Market Expansion and Competitive Advantage

Eco-friendly packaging opens doors to new markets and demographics, particularly those with a strong emphasis on sustainability. For instance, millennial and Gen Z consumers, who represent a growing share of purchasing power, prioritize ethical and environmentally responsible brands. By catering to these segments, businesses can tap into lucrative opportunities and expand their customer base. Furthermore, sustainable packaging appeals to institutional buyers, such as retailers and distributors, who are increasingly incorporating environmental criteria into their procurement processes.

From a competitive standpoint, businesses that pioneer innovative packaging solutions gain a first-mover advantage, setting industry benchmarks and influencing consumer expectations. Early adopters of eco-friendly practices often establish themselves as thought leaders, garnering media attention and industry recognition. This heightened visibility not only reinforces brand authority but also attracts top talent, investors, and partners who share a commitment to sustainability.

Innovation-Driven Revenue Streams

The shift toward sustainable packaging fosters a culture of innovation, spurring the development of new products, services, and revenue streams. For example, companies that invest in biodegradable or compostable packaging materials often uncover opportunities to diversify their offerings, such as launching subscription-based refill programs or reusable container initiatives. These models not only generate recurring revenue but also deepen customer engagement by encouraging sustainable consumption habits.

Additionally, businesses that collaborate with startups, research institutions, and technology providers to advance sustainable packaging solutions can monetize their innovations through licensing agreements or joint ventures. By leveraging intellectual property and proprietary technologies, companies can create additional income streams while reinforcing their leadership in the sustainability space.

Long-Term Financial Resilience

Perhaps the most compelling economic argument for eco-friendly packaging is its contribution to long-term financial resilience . As environmental concerns continue to shape consumer behavior and regulatory frameworks, businesses that fail to adapt risk obsolescence. Conversely, those that embrace sustainability are better equipped to thrive in a rapidly changing market. By reducing waste, conserving resources, and aligning with global sustainability trends, companies can future-proof their operations and ensure sustained profitability.

Investors are increasingly factoring environmental, social, and governance (ESG) criteria into their decision-making processes, favoring businesses with robust sustainability strategies. Companies that demonstrate a commitment to eco-friendly practices often enjoy access to favorable financing terms, lower capital costs, and higher valuations. This financial advantage enables them to reinvest in innovation, expand their market reach, and maintain a competitive edge.

Conclusion: A Strategic Investment in the Future

The economic benefits of adopting eco-friendly packaging extend far beyond cost savings, encompassing enhanced brand value, regulatory compliance, market expansion, and long-term resilience. By viewing sustainability as a strategic investment rather than a cost center, businesses can unlock new opportunities for growth and differentiation. In an era defined by environmental challenges and shifting consumer preferences, eco-friendly packaging represents not only a moral obligation but also a pathway to enduring success.

The Intersection of Renewable Energy and Eco-Friendly Packaging

The convergence of renewable energy and eco-friendly packaging represents a transformative synergy that amplifies the environmental and economic benefits of sustainability initiatives. By integrating renewable energy into the production and lifecycle management of sustainable packaging, businesses can create a holistic framework that maximizes resource efficiency, minimizes waste, and accelerates progress toward a circular economy. This symbiotic relationship underscores the interconnectedness of energy and materials, offering a blueprint for addressing some of the most pressing environmental challenges of our time.

Powering Sustainable Manufacturing with Renewable Energy

At the core of this intersection lies the application of renewable energy to power the production of eco-friendly packaging materials. Manufacturing processes for sustainable materials, such as bioplastics, mushroom packaging, and recycled composites, often require significant energy inputs. By sourcing this energy from renewable sources like solar , wind , and biomass , businesses can ensure that their packaging solutions remain environmentally responsible throughout their lifecycle. For instance, the production of PLA (polylactic acid), a popular bioplastic, involves energy-intensive fermentation and polymerization stages. Transitioning to renewable energy for these processes eliminates the carbon emissions associated with fossil fuel-based electricity, reinforcing the sustainability credentials of the final product.

Renewable energy also supports the development of advanced recycling technologies, which are critical for closing the loop in packaging materials. Techniques such as chemical recycling and pyrolysis require substantial energy to break down complex polymers into their base components for reuse. By powering these processes with clean energy, manufacturers can produce high-quality recycled materials without exacerbating their environmental footprint. This approach not only enhances the viability of recycled packaging but also promotes the adoption of circular economy principles, where materials are continuously cycled back into production.

Energy-Efficient Supply Chains

The integration of renewable energy extends beyond manufacturing to encompass the entire supply chain, from raw material sourcing to distribution. Sustainable packaging materials often rely on agricultural byproducts, plant-based feedstocks, or recycled inputs, which must be transported and processed efficiently. Renewable energy-powered logistics, including electric vehicles (EVs) and energy-efficient warehouses, play a pivotal role in reducing the carbon footprint of these operations. For example, companies utilizing EV fleets powered by solar or wind-generated electricity can significantly cut emissions associated with the transportation of packaging materials.

Similarly, renewable energy can optimize warehousing and distribution centers by powering automated systems, lighting, and climate control. Smart energy management systems equipped with renewable energy sources enable real-time monitoring and optimization of energy usage, ensuring that facilities operate at peak efficiency. This not only reduces operational costs but also aligns with sustainability goals, creating a seamless flow of eco-friendly materials through the supply chain.

Lifecycle Management and End-of-Life Solutions

Renewable energy also enhances the lifecycle management of eco-friendly packaging, particularly during the end-of-life phase. Composting facilities, which process biodegradable and compostable packaging materials, require energy for temperature regulation, microbial activity, and waste sorting. By incorporating renewable energy into these facilities, businesses can ensure that the decomposition process remains carbon-neutral, preserving the environmental benefits of the packaging. For instance, anaerobic digestion systems powered by biogas derived from organic waste can generate renewable energy while simultaneously breaking down compostable materials, creating a closed-loop system.

In cases where packaging materials are designed for reuse, renewable energy supports the infrastructure needed for collection, cleaning, and redistribution. Refillable container programs, for example, rely on energy-efficient washing and sterilization processes to prepare containers for repeated use. By powering these processes with renewable energy, companies can maintain the integrity of their reusable packaging systems while minimizing their environmental impact.

Accelerating Innovation Through Synergistic Technologies

The intersection of renewable energy and eco-friendly packaging fosters innovation by encouraging the development of synergistic technologies. For instance, advancements in bioenergy —energy derived from organic materials—can directly support the production of sustainable packaging. Agricultural residues used in mushroom packaging or bioplastics can also serve as feedstock for bioenergy generation, creating a dual-purpose system that maximizes resource utilization. Similarly, breakthroughs in nanotechnology and advanced materials are enabling the creation of packaging solutions that integrate renewable energy components, such as photovoltaic coatings or energy-harvesting films.

These innovations highlight the potential for renewable energy and eco-friendly packaging to co-evolve, driving mutual advancements that benefit both industries. Collaborative efforts between researchers, manufacturers, and policymakers are essential to unlocking this potential, ensuring that emerging technologies are scalable, cost-effective, and aligned with sustainability goals.

Economic and Environmental Synergies

The combined adoption of renewable energy and eco-friendly packaging yields significant economic and environmental synergies. Businesses that integrate these strategies can achieve greater operational efficiency, reduced energy costs, and enhanced brand equity, all while contributing to global sustainability targets. For example, companies that power their packaging production with renewable energy can market their products as "carbon-neutral" or "climate-positive," appealing to environmentally conscious consumers and stakeholders. This alignment with consumer values not only drives sales but also strengthens brand loyalty and market positioning.

From an environmental perspective, the synergy between renewable energy and sustainable packaging addresses multiple facets of ecological degradation. By reducing reliance on fossil fuels and minimizing waste generation, businesses can mitigate their contributions to climate change, resource depletion, and pollution. This holistic approach not only protects ecosystems but also fosters resilience in the face of environmental challenges, ensuring long-term viability for both businesses and the planet.

A Blueprint for a Sustainable Future

The intersection of renewable energy and eco-friendly packaging exemplifies the power of integrated sustainability strategies. By leveraging renewable energy to support the production, distribution, and lifecycle management of sustainable packaging, businesses can create a self-reinforcing cycle of environmental and economic benefits. This synergy not only addresses immediate challenges but also lays the foundation for a more sustainable and resilient future, where energy and materials work in harmony to meet the needs of both humanity and the planet.

Challenges and Limitations of Implementing Eco-Friendly Packaging

While the adoption of eco-friendly packaging presents numerous benefits, its implementation is not without significant challenges and limitations. These obstacles span technical, economic, logistical, and behavioral dimensions, often requiring businesses to navigate complex trade-offs and systemic barriers. Understanding these challenges is crucial for developing effective strategies to overcome them and ensuring the successful integration of sustainable packaging solutions into mainstream practices.

High Initial Costs and Investment Barriers

One of the most pervasive challenges in implementing eco-friendly packaging is the high initial cost associated with transitioning from traditional materials and processes. Developing and scaling sustainable alternatives often requires substantial investments in research and development, specialized equipment, and new supply chains. For small and medium-sized enterprises (SMEs), these upfront costs can be prohibitive, limiting their ability to adopt eco-friendly solutions. Even for larger corporations, the financial burden of retrofitting existing facilities or establishing new production lines can strain budgets and delay implementation timelines.

Moreover, the cost of raw materials for sustainable packaging, such as bioplastics or plant-based composites, tends to be higher than their conventional counterparts. While economies of scale and technological advancements are gradually reducing these costs, the current price differential remains a deterrent for many businesses operating on tight margins. This economic barrier is compounded by the uncertainty surrounding long-term returns on investment, particularly in markets where consumer willingness to pay a premium for sustainable products is inconsistent.

Limited Infrastructure for Recycling and Composting

The effectiveness of eco-friendly packaging is heavily reliant on the availability of appropriate end-of-life infrastructure , such as recycling facilities and industrial composting systems. However, the global infrastructure for managing sustainable packaging materials remains underdeveloped, posing a significant limitation. For instance, compostable packaging requires specific conditions—such as high temperatures and microbial activity—to break down effectively, yet many regions lack the necessary composting facilities to process these materials at scale.

Similarly, the recycling infrastructure for certain types of sustainable packaging, such as multilayer films or bio-based plastics, is often inadequate. These materials may not be compatible with existing recycling streams, leading to contamination and reduced recycling rates. Without robust systems in place to handle the unique requirements of eco-friendly packaging, businesses risk undermining their sustainability efforts and alienating environmentally conscious consumers who expect proper disposal options.

Performance and Durability Constraints

Another challenge lies in the performance limitations of some eco-friendly packaging materials compared to traditional options. While innovations have significantly improved the functionality of sustainable alternatives, certain applications still present technical hurdles. For example, biodegradable plastics often lack the strength, flexibility, or barrier properties required for packaging perishable goods or liquids. This can result in compromised product protection, shorter shelf lives, and increased spoilage, ultimately negating the intended environmental benefits.

Additionally, the durability of some sustainable materials, such as mushroom packaging or paper-based composites, may not meet the demands of rigorous supply chains or harsh environmental conditions. These limitations can deter businesses from adopting eco-friendly solutions, particularly in industries where packaging performance is critical to maintaining product quality and safety.

Consumer Awareness and Behavioral Resistance

The success of eco-friendly packaging also hinges on consumer behavior , which can present significant challenges. Despite growing awareness of environmental issues, many consumers remain unfamiliar with the proper disposal methods for sustainable packaging. Misunderstandings about terms like "biodegradable" and "compostable" often lead to improper disposal, with materials ending up in landfills or contaminating recycling streams. This disconnect between intention and action undermines the environmental benefits of eco-friendly packaging and highlights the need for extensive consumer education campaigns.

Behavioral resistance further complicates adoption, as some consumers may resist changes in packaging formats or aesthetics. For instance, the shift from glossy, rigid plastics to matte, biodegradable alternatives may be perceived as a downgrade in quality, even if the new materials perform equally well. Overcoming these perceptions requires targeted marketing efforts and transparent communication about the benefits and proper use of sustainable packaging.

Supply Chain Complexity and Scalability Issues

Implementing eco-friendly packaging often introduces supply chain complexities that can hinder scalability. Sourcing raw materials for sustainable packaging, such as agricultural byproducts or plant-based polymers, may involve navigating fragmented supply networks or dealing with seasonal variability. This can lead to inconsistencies in material availability and quality, complicating production planning and increasing operational risks.

Scaling production to meet global demand presents another challenge, particularly for innovative materials like mushroom packaging or edible films. These solutions often require specialized cultivation or manufacturing processes that are difficult to replicate at scale. As a result, businesses may struggle to achieve the volume and consistency needed to compete with traditional packaging options, delaying widespread adoption.

Regulatory and Standardization Gaps

The lack of standardized regulations and certifications for eco-friendly packaging creates additional hurdles for businesses. While some regions have implemented guidelines for biodegradability and recyclability, these standards vary widely across jurisdictions, leading to confusion and inconsistency. For example, a packaging material deemed compostable in one country may not meet the criteria in another, complicating international trade and compliance efforts.

Furthermore, the absence of universally recognized certifications for sustainable packaging can erode consumer trust and create opportunities for greenwashing. Businesses must navigate this regulatory landscape carefully, ensuring that their claims align with credible standards while advocating for greater harmonization and transparency in certification processes.

Technological and Innovation Gaps

Despite rapid advancements, there remain technological gaps in the development of eco-friendly packaging solutions. Certain applications, such as flexible packaging for snacks or beverages, still lack viable sustainable alternatives that match the performance of traditional materials. Bridging these gaps requires sustained investment in research and development, as well as collaboration between academia, industry, and government stakeholders.

Innovation is also constrained by the pace of technological adoption. Even when breakthrough solutions emerge, integrating them into existing manufacturing processes can be time-consuming and costly. This lag in implementation slows the transition to sustainable packaging and limits its impact on reducing environmental harm.

Addressing the Challenges for a Sustainable Future

The challenges and limitations of implementing eco-friendly packaging underscore the complexity of transitioning to a more sustainable model. However, these obstacles are not insurmountable. By addressing high costs through policy incentives, investing in infrastructure development, and fostering consumer education, businesses can create an enabling environment for sustainable packaging to thrive. Collaboration across industries and sectors will be essential to overcoming technical and logistical barriers, ensuring that eco-friendly solutions can scale effectively and deliver on their environmental promises.

Accessibility: Ensuring Inclusive Adoption of Eco-Friendly Packaging

The widespread adoption of eco-friendly packaging hinges not only on its environmental benefits but also on its accessibility to diverse populations and industries. Accessibility encompasses affordability, availability, ease of use, and inclusivity, ensuring that sustainable packaging solutions can be seamlessly integrated into daily life without creating barriers for marginalized groups or underserved markets. This section explores the measures being taken to enhance the accessibility of eco-friendly packaging, highlighting initiatives that promote equitable participation in the transition to sustainability.

Affordability Through Economies of Scale and Policy Support

One of the primary factors influencing accessibility is affordability , which remains a significant barrier for many consumers and businesses. While the cost of eco-friendly packaging materials has decreased over time, it still often exceeds that of traditional options, particularly for small-scale users. To address this challenge, governments and industry leaders are implementing strategies to drive down costs and make sustainable packaging more financially viable.

Economies of scale play a critical role in reducing prices, as increased production volumes lead to lower per-unit costs. Large corporations that commit to sourcing sustainable packaging materials can leverage their purchasing power to negotiate favorable terms with suppliers, creating a ripple effect that benefits smaller players in the supply chain. For example, multinational retailers adopting biodegradable packaging for private-label products can stimulate demand, encouraging manufacturers to scale up production and pass on cost savings to consumers.

Government policies also play a pivotal role in enhancing affordability. Subsidies, tax incentives, and grants for businesses investing in sustainable packaging technologies help offset initial costs and encourage adoption. Programs that provide financial assistance to SMEs for transitioning to eco-friendly practices ensure that smaller entities are not left behind in the sustainability movement. Additionally, public-private partnerships can facilitate the development of affordable packaging solutions tailored to local needs, particularly in low-income regions.

Expanding Availability Through Localized Production

Availability is another cornerstone of accessibility, and localized production is emerging as a powerful strategy to ensure that eco-friendly packaging materials are widely accessible. By decentralizing production and establishing manufacturing hubs closer to end-users, businesses can reduce logistical complexities, lower transportation costs, and minimize the environmental impact associated with long-distance shipping. This approach not only enhances the availability of sustainable packaging but also fosters regional economic development.

Localized production is particularly beneficial for materials like bioplastics , recycled paper , and mushroom packaging , which rely on region-specific feedstocks such as agricultural waste, plant fibers, or mycelium. For instance, regions abundant in sugarcane or corn can establish bioplastic production facilities to convert these crops into PLA (polylactic acid) or other bio-based polymers. Similarly, areas with significant agricultural byproducts can leverage mushroom packaging technologies to create durable, compostable solutions tailored to local markets.

The adoption of modular manufacturing systems further supports localized production by enabling scalable and flexible operations. These systems allow businesses to set up small-scale production units that can be easily adjusted based on demand, ensuring consistent supply without overproduction. Modular approaches also facilitate innovation, as they enable rapid prototyping and testing of new materials in response to evolving consumer preferences and regulatory requirements.

Simplifying Use Through Consumer-Centric Design

Ease of use is a critical factor in ensuring that eco-friendly packaging is accessible to all demographics, including those with limited technical knowledge or physical abilities. Packaging designs must prioritize simplicity, clarity, and functionality to eliminate barriers to adoption. For example, intuitive labeling that clearly communicates disposal instructions—such as "compostable," "recyclable," or "reuse instructions"—empowers consumers to make informed decisions about proper waste management.

Innovations in smart packaging are also enhancing usability by integrating technology that simplifies interactions. QR codes, NFC tags, and augmented reality features embedded in packaging provide users with instant access to information about product origins, disposal methods, and sustainability credentials. These tools bridge the gap between consumers and complex recycling or composting processes, making it easier for individuals to participate in circular economy initiatives.

For populations with disabilities or mobility challenges, inclusive design principles ensure that eco-friendly packaging remains accessible. Features such as easy-open mechanisms, lightweight materials, and ergonomic shapes cater to diverse needs, ensuring that no group is excluded from benefiting from sustainable solutions. Collaborations between designers, disability advocates, and manufacturers are essential to developing packaging that is both environmentally responsible and universally usable.

Promoting Inclusivity Through Community Engagement

Inclusivity extends beyond physical accessibility to encompass equitable participation in the sustainability movement. Community engagement initiatives play a vital role in raising awareness and fostering acceptance of eco-friendly packaging among underserved populations. Educational campaigns, workshops, and partnerships with local organizations help demystify sustainable practices and address misconceptions about green alternatives.

For example, programs targeting low-income communities often focus on the affordability and practicality of reusable packaging systems, such as refill stations for household goods. These initiatives not only reduce reliance on single-use plastics but also empower participants to adopt sustainable habits that align with their financial realities. Similarly, collaborations with schools and youth organizations instill environmental values in younger generations, creating a foundation for long-term behavioral change.

Businesses can also enhance inclusivity by tailoring packaging solutions to cultural and regional preferences. For instance, designing eco-friendly packaging that respects traditional aesthetics or incorporates locally sourced materials resonates more deeply with specific communities, increasing acceptance and adoption rates. This culturally sensitive approach ensures that sustainability efforts are perceived as relevant and respectful, rather than imposed or alienating.

Addressing Accessibility Gaps in Rural and Remote Areas

Rural and remote areas often face unique challenges in accessing eco-friendly packaging due to limited infrastructure, sparse populations, and higher transportation costs. To bridge these gaps, innovative distribution models and alternative delivery systems are being developed. Mobile recycling units, pop-up composting facilities, and community-based collection programs bring sustainable practices directly to underserved regions, ensuring that geographic isolation does not preclude participation in the circular economy.

Digital platforms and e-commerce channels further expand accessibility by connecting rural consumers with eco-friendly products and packaging options. Online marketplaces specializing in sustainable goods enable individuals in remote areas to purchase biodegradable or reusable packaging materials that may not be available locally. Additionally, subscription services for refillable containers or bulk goods reduce the need for frequent trips to urban centers, saving time and resources for rural households.

Fostering Global Accessibility Through Collaboration

Achieving global accessibility requires collaboration across industries, governments, and international organizations. Multinational corporations, NGOs, and research institutions are working together to develop affordable, scalable, and culturally appropriate packaging solutions that can be implemented worldwide. Initiatives like the Ellen MacArthur Foundation’s New Plastics Economy and the UN Environment Programme’s Sustainable Consumption and Production Clearinghouse serve as platforms for sharing best practices, funding innovations, and coordinating efforts to address systemic barriers.

Public-private partnerships are instrumental in driving progress, particularly in developing countries where access to sustainable packaging remains limited. For example, joint ventures between governments and private companies can establish local recycling and composting facilities, creating jobs while improving waste management infrastructure. International aid programs and grants further support capacity-building efforts, enabling communities to adopt eco-friendly practices without compromising economic stability.

Conclusion: A Commitment to Universal Access

Ensuring the accessibility of eco-friendly packaging is not merely a logistical challenge but a moral imperative. By prioritizing affordability, expanding availability through localized production, simplifying use through thoughtful design, and promoting inclusivity through community engagement, stakeholders can create a future where sustainable packaging is accessible to all. Addressing the unique needs of rural and remote areas, alongside fostering global collaboration, will further solidify the foundation for universal adoption. Accessibility lies at the heart of the sustainability movement, and its realization will pave the way for a more equitable and environmentally conscious world.

How to Transition to Eco-Friendly Packaging: A Step-by-Step Guide

Transitioning to eco-friendly packaging is a multifaceted process that requires careful planning, strategic execution, and ongoing evaluation. Businesses aiming to adopt sustainable packaging solutions must navigate a range of considerations, from assessing current practices to implementing scalable innovations. This section provides a comprehensive roadmap for organizations seeking to transition effectively, offering actionable steps and insights to ensure a smooth and impactful shift toward sustainability.

Step 1: Conduct a Comprehensive Packaging Audit

The first step in transitioning to eco-friendly packaging is to conduct a thorough packaging audit . This involves evaluating existing packaging materials, processes, and supply chains to identify areas for improvement. Begin by cataloging all packaging components used across product lines, noting their composition, lifecycle impacts, and disposal requirements. Assess the environmental footprint of each material, considering factors such as greenhouse gas emissions, resource consumption, and waste generation.

Engage key stakeholders, including procurement teams, suppliers, and logistics partners, to gather insights into current practices and pain points. This collaborative approach ensures a holistic understanding of the organization's packaging ecosystem and highlights opportunities for optimization. Additionally, benchmark your findings against industry standards and competitors to identify gaps and set realistic goals for improvement.

Step 2: Define Clear Sustainability Goals and Metrics

Once the audit is complete, define clear and measurable sustainability goals that align with your organization's broader mission and values. These goals should address specific environmental priorities, such as reducing plastic usage, increasing recyclability, or achieving carbon neutrality in packaging operations. Establishing quantifiable targets—such as "reduce plastic packaging by 50% within three years" or "source 100% of packaging materials from renewable sources by 2030"—provides a framework for accountability and progress tracking.

To monitor success, implement robust metrics and key performance indicators (KPIs) tailored to your sustainability objectives. Examples include the percentage of packaging materials recycled or composted, reductions in packaging weight and volume, and energy savings achieved through renewable integration. Regularly review these metrics to assess progress, identify areas for refinement, and celebrate milestones to maintain momentum.

Step 3: Research and Select Appropriate Eco-Friendly Materials

With goals in place, the next step is to research and select eco-friendly packaging materials that meet your operational and sustainability requirements. Explore a wide range of options, including bioplastics, recycled paper, mushroom packaging, and compostable films, evaluating their performance, cost-effectiveness, and compatibility with your products. Consider factors such as durability, barrier properties, shelf life, and aesthetic appeal to ensure that selected materials align with brand identity and customer expectations.

Collaborate with suppliers and material innovators to stay informed about the latest advancements in sustainable packaging. Request samples and conduct pilot tests to assess how new materials perform under real-world conditions. Engage cross-functional teams, including marketing, design, and quality assurance, to evaluate the feasibility of integrating these materials into existing workflows and product lines.

Step 4: Optimize Packaging Design for Sustainability

Optimizing packaging design is a critical step in minimizing environmental impact while maintaining functionality. Adopt a design-for-sustainability approach that prioritizes material efficiency, modularity, and ease of disposal. Simplify packaging structures to reduce material usage and eliminate unnecessary components, such as excessive layers or non-recyclable adhesives. Incorporate standardized dimensions to improve logistics efficiency and maximize load capacity during transportation.

Leverage digital tools and software to simulate and refine packaging designs before production. Advanced modeling techniques enable businesses to test various configurations, identifying optimal solutions that balance sustainability, cost, and performance. Additionally, consider incorporating reusable or refillable elements into packaging designs to extend product lifecycles and reduce waste generation.

Step 5: Integrate Renewable Energy into Production Processes

To further enhance sustainability, integrate renewable energy into packaging production processes. Evaluate opportunities to power manufacturing facilities, warehouses, and distribution centers with clean energy sources such as solar, wind, or biomass. Install on-site renewable energy systems, such as photovoltaic panels or wind turbines, to generate electricity and reduce reliance on fossil fuels.

Partner with renewable energy providers to secure off-site energy credits or participate in community solar programs. Implement energy management systems to monitor and optimize energy consumption, ensuring that renewable energy is utilized efficiently across operations. By aligning packaging production with renewable energy initiatives, businesses can achieve significant reductions in carbon emissions and operational costs.

Step 6: Develop a Robust Supply Chain Strategy

A successful transition to eco-friendly packaging requires a robust supply chain strategy that supports the sourcing, production, and distribution of sustainable materials. Collaborate with suppliers to establish transparent and ethical sourcing practices, prioritizing materials derived from renewable or recycled sources. Negotiate long-term contracts to secure stable pricing and availability, mitigating risks associated with market fluctuations.

Invest in supply chain visibility tools to track the journey of packaging materials from origin to end-of-life, ensuring compliance with sustainability standards. Streamline logistics by optimizing transportation routes, consolidating shipments, and adopting energy-efficient vehicles. Explore partnerships with third-party logistics providers specializing in sustainable practices to enhance supply chain resilience and efficiency.

Step 7: Educate and Engage Stakeholders

Education and engagement are essential for fostering buy-in and driving behavioral change across the organization. Develop comprehensive training programs to educate employees about the importance of eco-friendly packaging and their role in achieving sustainability goals. Highlight the environmental and economic benefits of transitioning to sustainable materials, emphasizing the positive impact on brand reputation and customer loyalty.

Extend educational efforts to external stakeholders, including customers, retailers, and distributors. Launch marketing campaigns that communicate the value proposition of eco-friendly packaging, using storytelling and data-driven insights to build trust and credibility. Provide clear instructions for proper disposal and recycling, empowering consumers to participate actively in the circular economy.

Step 8: Monitor, Evaluate, and Iterate

Finally, establish a continuous improvement cycle by regularly monitoring, evaluating, and iterating on your eco-friendly packaging initiatives. Collect feedback from internal teams, customers, and partners to identify areas for enhancement and address emerging challenges. Leverage data analytics to analyze performance metrics, uncover trends, and inform decision-making.

Stay abreast of technological advancements and industry developments to remain competitive and innovative. Participate in sustainability forums, conferences, and networks to exchange knowledge and collaborate on best practices. By maintaining a proactive and adaptive approach, businesses can refine their strategies, scale successful initiatives, and achieve lasting impact in the transition to eco-friendly packaging.

Conclusion: Embracing a Sustainable Future Through Eco-Friendly Packaging

The journey toward sustainability is one of the most defining challenges and opportunities of our time, and eco-friendly packaging stands at the forefront of this transformative movement. As businesses, consumers, and policymakers increasingly recognize the urgent need to address environmental degradation, the adoption of sustainable packaging solutions has emerged as a critical lever for driving meaningful change. By reimagining the materials, processes, and systems that underpin packaging, we can collectively mitigate the ecological footprint of commerce while fostering a more resilient and equitable future.

Throughout this article, we have explored the intricate relationship between sustainability , renewable energy , and eco-friendly packaging , highlighting their interconnected roles in shaping a greener economy. From the environmental toll of traditional packaging materials to the innovative potential of bioplastics, mushroom packaging, and smart technologies, it is evident that sustainable alternatives offer viable pathways to reducing pollution, conserving resources, and closing the loop in material lifecycles. The integration of renewable energy into packaging production further amplifies these benefits, enabling businesses to align their operations with climate goals while achieving cost savings and operational efficiencies.

However, the transition to eco-friendly packaging is not without its challenges. High initial costs, limited infrastructure, performance constraints, and consumer resistance underscore the complexity of this endeavor. Yet, these obstacles are not insurmountable. By leveraging economies of scale, investing in research and development, fostering collaboration, and prioritizing accessibility, businesses can overcome barriers and unlock the full potential of sustainable packaging. The examples of pioneering companies and innovative startups demonstrate that leadership in sustainability is not only possible but also profitable, yielding enhanced brand equity, market differentiation, and long-term resilience.

As we look to the future, the imperative for action has never been clearer. The convergence of consumer demand, regulatory pressures, and technological advancements creates a fertile ground for innovation and transformation. Businesses that embrace eco-friendly packaging today position themselves as stewards of change, setting benchmarks for the industry and inspiring others to follow suit. Moreover, the ripple effects of sustainable practices extend beyond corporate boundaries, influencing supply chains, communities, and ecosystems worldwide.

Ultimately, the transition to eco-friendly packaging is not merely a business decision but a collective responsibility. It calls upon all stakeholders—manufacturers, retailers, consumers, and policymakers—to work together in pursuit of a shared vision: a world where commerce thrives in harmony with nature. By committing to sustainable practices, investing in renewable energy, and championing accessibility and inclusivity, we can redefine the role of packaging in society and pave the way for a brighter, more sustainable future.

10 Frequently Asked Questions (FAQs) About Eco-Friendly Packaging

-

What is eco-friendly packaging?

Eco-friendly packaging refers to materials and designs that minimize environmental impact by being biodegradable, recyclable, reusable, or derived from renewable resources. -

Why is eco-friendly packaging important?

It reduces pollution, conserves natural resources, lowers carbon emissions, and addresses growing consumer demand for sustainable products. -

What are some examples of eco-friendly packaging materials?

Examples include bioplastics, recycled paper, mushroom packaging, seaweed-based films, and compostable bags. -

Is eco-friendly packaging more expensive than traditional packaging?

While initial costs may be higher, economies of scale, government incentives, and long-term savings often offset the expense. -

How can businesses reduce the cost of eco-friendly packaging?

Strategies include optimizing designs, sourcing locally, leveraging subsidies, and scaling production to achieve cost efficiencies. -

What role does renewable energy play in sustainable packaging?

Renewable energy powers production processes, reduces carbon footprints, and supports circular economy initiatives. -

Can eco-friendly packaging match the performance of traditional materials?

Advances in technology have significantly improved the strength, flexibility, and barrier properties of sustainable materials, making them competitive with conventional options. -

How do I ensure proper disposal of eco-friendly packaging?

Follow disposal instructions provided on packaging labels, such as composting or recycling guidelines, and advocate for improved waste management infrastructure. -

What are the biggest challenges in adopting eco-friendly packaging?

Challenges include high upfront costs, limited recycling/composting infrastructure, performance limitations, and consumer education gaps. -

How can small businesses transition to eco-friendly packaging?

Small businesses can start by auditing current practices, setting achievable goals, collaborating with suppliers, and educating customers about sustainable choices.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0